One of the biggest problems most CNC machine shop owners face is hiring and training employees to become independent operators in their shops.

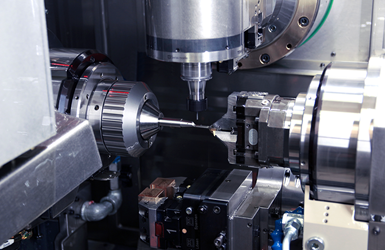

That means, machinists know how to set up, program, maching, and inspect the entire job without much or any guidance from senior level managers (or the owner!). Unfortunately, that’s not the reality for most shops. Creating a workforce of independent machinists has been top priority at Solmac Inc. since its inception in 2006. It’s critical to business success, because our customers demand the highest quality products at the best price and delivered on time.

For years, we’ve struggled hiring qualified CNC Machinists. I’ve struggle with hiring machinists who have good intentions, but shy away from taking responsibility for the finished product. Machinists ask repeated questions, worry about setting up jobs the wrong way, or making errors that lead to scrapped parts or machine crashes.

Who’s to blame for this issue? In my opinion, there are troubles in various areas. First, many machinists aren’t trained properly to do the jobs they are asked to do. This creates fear of making mistakes and resistance to taking on more responsibility. Second, owners often fear letting go of the reins and micro-manage their teams, creating a similar outcome. Third, the workforce supply in the CNC machining industry is scarce as the supply of new talent declines because qualified machinists chose jobs in other areas.

So, what’s the solution?

In 2017, Boris Soldo, founder of Solmac Inc, had the idea of streamlining his operations and eliminating these issues with the help of a software. After an extensive search, he discovered that such a software did not exist. So, he decided to build it. That’s how shopGURU was born.

Since then, shopGURU has been the key to success in his operations. Boris Soldo said, “It allows me to record the exact steps I take to produce even the most precise and intricate parts including setup, tooling, workholding, machining, and event inspection. I have every step documented and even include pictures of the parts.” Once a job is documented, it can be replayed with ease in shopGURU. This empowers even junior machinists to approach the most intricate parts with full confidence. As a result, machinists complete the jobs faster and error-free. It gives him the ability to feel confident and self-sufficient. Machinists feel confident, which boosts job satisfaction and morale. Boris Soldo and his management team enjoy less time on the shop floor helping machinists and troubleshooting errors – and spend more time on building the business (and taking well-deserved time off!). “Ultimately, the greatest winners are our clients,” Boris said. “Our customers know that they can rely on us 100% of the time to produce their parts with accuracy and on time. shopGURU helps me accomplish just that.”

He recommends shopGURU for small and large manufacturing environments with CNC applications. shopGURU can be implemented in one-man shops as well as facilities with hundreds or thousands of team members. It’s fully scalable and works with precision, every time.

Let us provide you with a personalized Demo to show what shopGURU can do for your machining needs.

0 Comments